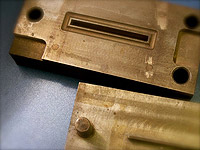

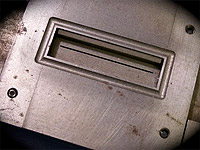

Some of the finest toolmakers in the country are located in Dayton, Ohio. For 53 years, C & M Rubber Co. has worked with many toolmakers to produce high quality and durable tooling. The tools range from a simple o-rings to parts consisting of sophisticated, geometrical curves with challenging dimensional tolerances. Ultimately, our customers enjoy the benefit of our years of tooling and molding experience by incorporating our proprietary know-how into their tooling. These unique techniques contribute to a dimensionally true part that costs less to mold and process into a finished part. The best news is we can accomplish all of this within budget and on time.

Prototype Lead Time

As a general rule, discounting cueing delays as a result of heavy job scheduling demand and depending upon geometric complexity, a single cavity prototype can be completed in as few as 15 days. To minimize delivery disappointment, it is recommended that a date is established prior to “cutting steel”.

Production Tool Lead Time

As a general rule, it is recommended that you allow at least 75 days and sometimes 90 days for production tool completion. If you are looking at constructing a liquid injection mold, lead times can range from 90 to 120 days due to the tight tolerances required for successful tool performance.

There are many factors that affect tooling delivery, including:

- The geometric complexity of the molded part is a prominent factor in the lead-time required to complete a mold (tool). Some molded shapes require complex, multi-stage cutting and the use of sophisticated CNC machines to create the finished product.

- The higher the cavity count, the longer it will take to complete a mold.

- The closer the dimensional tolerances, the longer the lead-time will be.

- Dimensional changes processed after steel cutting has commenced will extend the lead-time and may require abandoning the current tooling project and starting over.