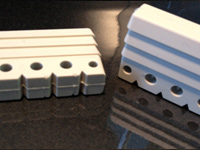

C & M Rubber Co. was contracted by a manufacturer of medical equipment to mold a silicone foot shown here. The foot is installed on the supporting legs of their examination tables, and is designed to prevent scuffing of tile or linoleum floors, or skidding on commercial carpeting.

Originally this job was tooled as a transfer mold consisting of 49 cavities; however, after years of service, the tool was scheduled to be reworked to correct a registration issue that had developed over time. It was decided that retooling for liquid injection molding (LIM) was more cost-effective, and would avoid price increase to the customer. The LIM parts eliminated a direct labor cost and the expense of cryogenic de-flashing of the silicone foot.

Composed of LR 3003/60 Shore A Durometer silicone rubber, the foot was manufactured on our Boy 22 liquid injection molding unit, which features a fluid automation pump set. This advanced manufacturing process allowed us to meet tolerances of ±.015″. In addition, we were also able to exactly match the customers color specification. Produced in blanket orders, we currently manufacture over 100,000 pieces annually.

To learn more about this project, or the processes used to manufacture it see the table below or contact us directly.