Our expertise in prototyping has resulted in the creation and manufacture of a wide range of rubber components for a variety of familiar devices. From ultra high-speed print heads to small surgical tool components to simple gaskets and seals, each started with a prototype.

What Is Involved In Prototyping A Rubber Component?

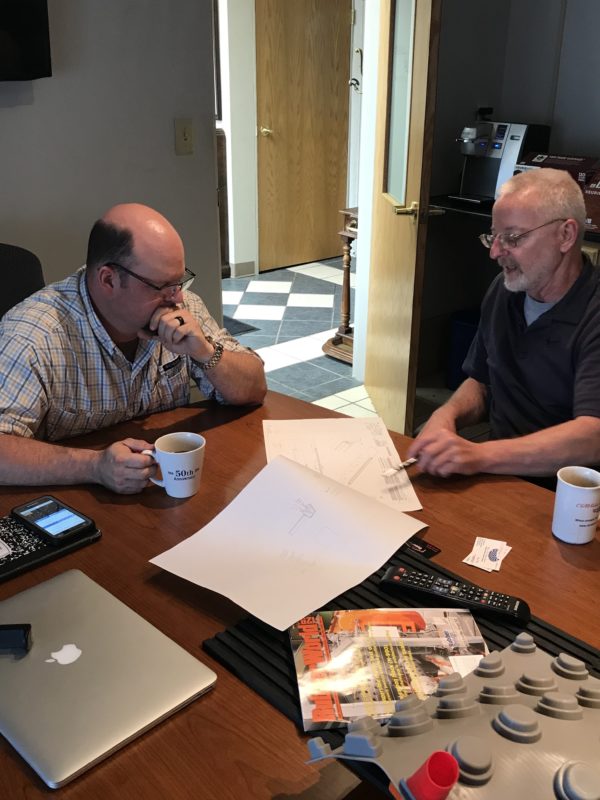

Whether you are starting from an initial design sketch or addressing a redesign issue, close collaboration with our engineering staff in the early stages of your project has been proven to successfully save significant expense in man-hours and thousands of dollars in development time. Tapping into the expertise accumulated over 53 years of custom rubber molding will simplify and abbreviate the time-consuming process of creating a prototype. Equipped with an understanding of the expected environmental conditions and the anticipated wear rigors of your particular application, we can recommend the material most suited for the job. Working closely with a host of local tool designers and fabricators, C & M Rubber engineers provide them with the required input and upon their completion review, the prepared prototype drawing(s) created for your part. Based upon a satisfactory client review, this phase is culminated with the preparation of a quotation for the prototype tooling and a proposed production tool based upon your anticipated annual requirement.

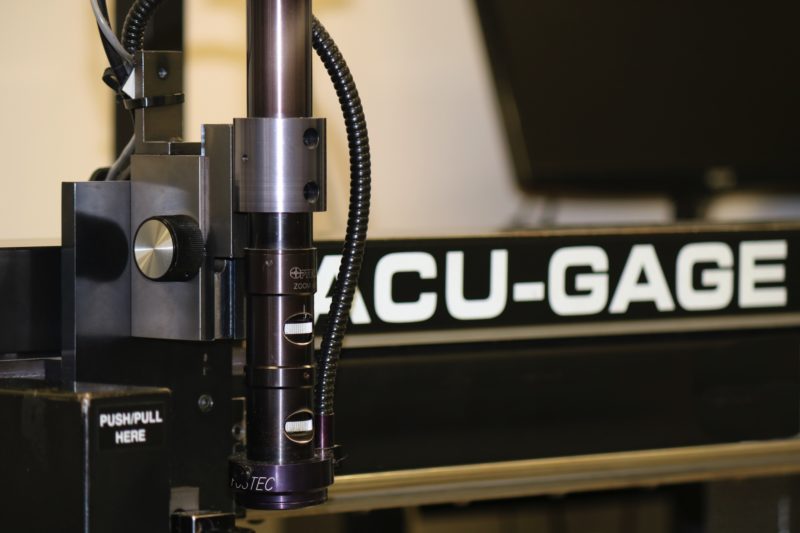

Upon receipt of your quotation approval, an order is placed with the tooling fabricator and the prototype tooling is prepared. Upon completion, a quality technician checks the tooling for dimensional accuracy and authorizes sample parts to be molded if all dimensions meet drawing specifications. The sample prototype parts are sent to our post-processing department for de-flashing /trimming and finally measured to ensure compliance with the drawing. Based upon successful first article QC inspection, the samples are forwarded to you for your inspection and product trials.