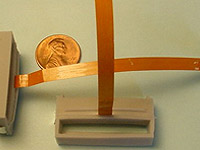

Another leading edge technology is a process used to encapsulate in silicone or other elastomers a variety of metal inserts, electronic sensors and low voltage heating elements.

With appropriate material selection and “outside the box thinking” when recommending a new tooling design, C & M Rubber Co. has been tagged by one customer as, “The company to go to when you’re looking for the impossible.” C & M Rubber Co. will collaborate with your organization on the most challenging and your simplest projects to produce a high quality and cost effective rubber part.